6 ANNUAL MAINTENANCE TASKS THAT KEEP HYDRAULIC CYLINDERS IN GOOD SHAPE

If you rely on power from a fluid hydraulic system at your industrial facility, then you need to keep up with hydraulic cylinder maintenance and prevent malfunctions that cause downtime.

The best thing you can do to keep up with maintenance is to establish a regular schedule that all of your staff members are aware of and can assist with. Sometimes, it is difficult to remember to keep up with annual maintenance tasks, more so than regular maintenance tasks, which are worked into everyday operations and thereby become second nature.

This post lists six maintenance tasks that you need to remember to carry out annually to ensure the continued functioning and maximize the lifespan of your hydraulic cylinders.

1. Ensuring a Quality Rod Finish

One of the most important considerations in hydraulic cylinder operation is the condition of the cylinder rod. If the rod becomes bent, then load shift could detract from cylinder operation and eventually lead to malfunctions. Other important considerations are the rod diameter and rod strength.

Regular inspections should involve checking the rod finish and ensuring that an excessively rough finish won't create seal leakage issues.

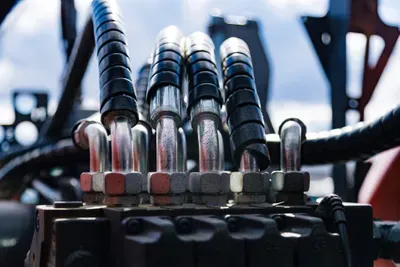

2. Inspecting Seals and Valves

A variety of seals and valves make up some of the most vital components of hydraulic cylinders.

Inspecting piston seals and rod seals can ensure that leaks won't allow cylinder drift to detract from cylinder efficiency or lead to malfunctions. The holding valve is another important component that could allow for contamination issues if it is not functioning properly.

3. Keeping Fluids Properly Conditioned

Hydraulic fluid needs to remain free from any contaminants and foreign materials. Aerated fluid should never be allowed into hydraulic cylinder systems because it could create problems with sound level.

As part of conditioning hydraulic cylinder fluids, the filtration system should be inspected to make sure that it is successfully preventing contamination and is not at risk of developing any clogs.

The hydraulic cylinder's filter will routinely need to be replaced to prevent fluid contamination issues as well as clog issues.

4. Examining the Cylinder Tube

Over time, a hydraulic cylinder tube can start ballooning. This typically occurs in situations where the cylinder wall is too thin or the cylinder is creating higher pressures than the cylinder material can support. When the cylinder tube balloons, fluid may be permitted to get past the seal and create a wide variety of issues including hydraulic fluid contamination.

5. Rotating Cylinders

Regular cylinder rotation can prevent downtime. Facilities should have cylinder spares available to be used in rotation schedules. This will keep cylinders fresh.

When cylinders have been taken apart to be rotated and inspected, seals can be replaced as necessary and an inspection can be performed on the hydraulic circuit.

Any varnish that is found during inspections indicates that oil is running too hot. This could be happening due to either the quality or quantity of the oil being used. Hot oil can also be a symptom of another mechanical problem or an oil leak.

6. Inspecting Accessories

Accessories of the hydraulic cylinder assembly need to be maintained to ensure proper functioning of the cylinder itself. These accessories include the clevises, ball joints, brackets, and rod eyes.

Accessories will wear out over time and will need to be serviced or replaced. If a clevis or pivot pin is in need of service, then slop and play between the joints and the cylinder will be noticed and misalignment could result. If this problem is not remedied as soon as possible, then a catastrophic failure of the entire hydraulic cylinder assembly could occur.

Not only should accessories be inspected annually, but also every time a cylinder is removed for service, inspection, or rotation.

If you're in need of sales or service on hydraulic cylinders at your facility, contact

Carolina Hose & Hydraulics.