2 KEY DIFFERENCES BETWEEN HOSES AND TUBES

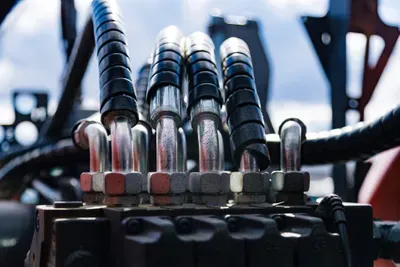

Hydraulic systems are an everyday part of the construction and industrial worlds, acting to power a wide variety of machinery and vehicles. These systems accomplish work through compressing liquids, and this compression almost always involves moving the hydraulic fluid through a series of hoses and tubes.

Many people mistakenly assume that the differences between tubes and hoses are negligible at best. Others even convince themselves that the two words designate the exact same component. Yet hoses and tubes remain quite distinct from one another, and they certainly cannot be expected to be swapped out for one another without potentially negative consequences.

If you would like to avoid problems and improve your knowledge of hydraulic system components, read on. This article will outline two key differences between hoses and tubes.

1. Lifespan

The difference between hoses and tubes comes down to two interrelated factors: rigidity and construction material. Simply put, hoses are flexible, while tubes are rigid. The flexibility of a hose requires that it be constructed from rubber, often reinforced with a metal mesh. Tubes, on the other hand, can be constructed completely from metal.

The metal construction of a tube gives it a much greater structural integrity - and thus a greater lifespan. It will also be less susceptible to damage, whether from friction, heat, or simply the rigors of daily use. Hydraulic tubes are also largely immune to damage from UV rays, which can damage the softer nature of hoses. Outdoor machinery can thus benefit from a greater use of tubes.

Tubes do have their Achilles' heel, however: vibration. The rigidity of a metal tube also tends to make it more brittle. When installed in a high vibration part of a hydraulic system, a tube may become damaged - or work loose - as time goes on. The flexible nature of hoses makes them much more impervious to damage when used in vibrating parts of the system.

Tubes also possess a greater degree of vulnerability to corrosion. This means that care must be taken to clean them regularly, removing any potentially destructive substances. Otherwise, they will negatively affect the lifespan of the tube. In general, hoses should be used in parts of a system that regularly come into contact with acidic or otherwise corrosive materials.

2. Hoses Can't Handle Heat

Hydraulic tubes have another key advantage over hoses: their ability to deal with heat. This stems from the fact that tubing can be painted - or taped up - in order to increase its reflective abilities. As a result, the tubing will absorb less heat. This helps to protect the tubing on a structural level.

Even more importantly, the reflective potential of tubing helps to keep the temperature of the hydraulic system itself within acceptable limits. As hydraulic fluid heats up, it leads to inefficiency in the system. Temperatures greater than 180 degrees Fahrenheit will also begin to seal compounds and even the hydraulic fluid itself.

Compared to tubing, hoses allow much more heat to penetrate into the hydraulic fluid. That heat will also cause the hoses themselves to expand. This can have a negative impact on the system's pressure, often causing the machine to run for longer periods of time in order to accomplish its task. It also makes the hoses susceptible to ruptures, which will render the system unusable until the hose has been replaced.

A hydraulic system requires both tubes and hoses in order to deliver the results you want. When the time comes to replace or upgrade such components, you will need to contact a hydraulic technician with the right kind of experience. For best results, please don't hesitate to

contact our hydraulic pros at Carolina Hose & Hydraulics.