COMMON CAUSES OF HEAVY EQUIPMENT FAILURES

Heavy equipment can break down due to mechanical issues, accidents, and operational misuse. Unfortunately, machinery failures are costly to fix and can lead to huge losses associated with the downtime. Therefore, prevention remains the best way to avoid losses and inconveniences.

However, since you can't prevent what you don't know the cause, you need to figure out what can make your heavy equipment break down. Discover the common causes of equipment failures.

Poor Maintenance

Just like vehicles, you need to maintain your heavy equipment to keep them in good shape. Therefore, you need to observe the equipment maintenance practices the manufacturer recommends. Don't overlook simple tasks, such as tire inspection, regular cleaning, and oil change.

Also, service your equipment regularly with professionals who check critical components such as the engine, gears, filters, or tires.

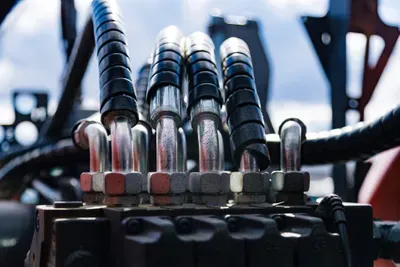

For example, since heavy equipment typically depends on the hydraulic pump, let the experts inspect it for any alarming signs. For instance, if they notice that the hydraulic fluid has debris, they will change it to prevent contamination.

These standard maintenance practices can significantly reduce breakdowns and increase the lifespan of your equipment.

Unskilled Operators

Equipment operators can either protect or mess up your heavy equipment. Inexperienced operators tend to make mistakes that can risk the integrity of your equipment. Therefore, you should only work with qualified operators.

If you upgrade your equipment, you can outsource operators or enroll your employees in a training program to improve their skills. During the training, they will learn about the new equipment features, operations, troubleshooting, safety precautions, or emergency responses.

Train several operators to avoid inconveniences when the main operators are absent. Remember to train your workers every time you purchase different equipment. This way, you can avoid downtime due to misuse or poor operation skills.

Failure to Observe Limits

Heavy equipment has a high maximum capacity, but that doesn't mean that you should always use them to that point. Overworking your machines will accelerate wear and tear, which could result in significant mechanical issues.

Therefore, your workers should observe the limits and take breaks after a few hours of working to allow the machines to rest. If you have to handle heavy workloads, start early enough to avoid the last-minute rush.

Improper Storage

Equipment storage is a vital aspect you shouldn't ignore. Outdoor storage exposes your machinery to harsh weather elements that could lead to damages.

For example, rain can accelerate corrosion, which can considerably affect your equipment's external and internal components. Also, too much heat in summer can affect the hydraulics.

Moreover, pests and rodents can access the equipment if you leave it out and chew wires and cables. Therefore, you might need to erect a temperature-controlled and pest-free storage facility to protect your equipment.

Use of Low-Quality Products

Low-quality products, such as oil, coolant, and hydraulic fluid, are almost always cheap but will cost you more in the long run. As much as they save you money upfront, they can lead to costly mechanical issues. For this reason, always value the quality of products over price.

Failure to Respond to Warning Signs

Most heavy equipment issues develop gradually, which means you might notice a couple of warning signs before the problem escalates. You can avoid huge expenses when you respond quickly on time. However, most people usually neglect these warning signs until the machine finally fails.

Examples of these warning signs include high fuel consumption, hissing or grinding sounds, low hydraulic pressure, or strange smells. Remind your operators to check the dashboard warning lights and seek assistance as early as possible.

You should take proper care of your equipment to prevent inconveniences and breakdowns. Our company offers hydraulics inspection, repair, and maintenance services. We are also a renowned hose dealer and can handle your hose, tubing, and fitting needs. If you need hydraulic specialists,

contact us now.