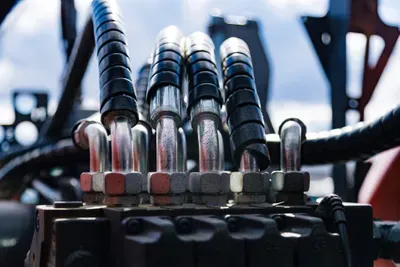

3 COMMON CAUSES OF OVERHEATING IN HYDRAULIC SYSTEMS

Hydraulic systems can overheat easily. Systems that experience frequent and sustained overheating issues will eventually fail, however, so it’s important to watch out for that. Here are some of the common causes of overheating in hydraulic systems and what you can do about them.

1. Your Hydraulic System Is Out of Balance

The components of your hydraulic system must work in harmony if you want the system to remain efficient and effective. Changes and adjustments to hydraulic systems can introduce problems that cause the system to fall out of balance and overheat.

Many people seek to adjust their hydraulic systems to eke out a little more performance from them. Adjustments aren't always an issue. Sometimes, adjustments are necessary for certain applications. However, if you're not sure of what you're doing, you should not make adjustments to your hydraulic system.

An increase in system pressure caused by adjusting the pump compensator is a common adjustment that leads to overheating. When adjusting the pump compensator setting, many people never adjust the relief valve setting along with it.

When the pump compensator setting matches or exceeds the relief valve settings, the relief will open and dump excess amounts of heat into the system. The compensator won't do its job, and all energy released will go back to the tank, rather than going through flow regulation.

Other attempts to change system pressure can also result in poor flow management and overheating. You can increase system pressure, but you should only do so by using the designer or manufacturer's recommended method and within recommended psi ranges.

2. Your Upgrades Don't Work Well With Your System

You can use multiple different upgrades and tuning methods on hydraulic systems. Many users will invest in upgrades that promise more flow and speed. The issue with these upgrades is that they're not always fit for the hydraulic systems they're applied to.

Since everything needs to stay in balance, you must make sure your upgrades match the entirety of your hydraulic system. For example, a higher flow pump can help give increased capabilities to a hydraulic system, but did you also check to see if the system's hoses and piping can handle that increase in flow?

The increased flow can hit your smaller hoses hard and require more pressure just to get through them. This goes for any part of the hydraulic system that isn't readily capable of handling more flow.

If a component becomes a flow throttle, the increase in pressure at the site can cause an overall pressure drop in the system. Also, the energy required to force flow will directly translate to an increase in heat, which lowers the systems efficiency and effectiveness.

When you make upgrades, also ascertain if you need to change other components. In the example of the higher flow pump, you can simply increase your hose size, and that makes all the difference.

3. Your System Components Need Replacing or Maintenance

Wear and tear on hydraulic system components can lead to overheating in various ways. Some overheating problems stem directly from a lack of maintenance on a hydraulic system. For example, a buildup of debris in the system can and will create a buildup of heat.

A faulty heat exchanger also has the capabilities of keeping a system hot when it shouldn't be. Have you checked your fluid? Low fluid or the wrong type of fluid will also cause overheating.

These are all the types of issues that show up with routine maintenance and care of a hydraulic system. That also means these are usually the easiest things to deal with.

Nevertheless, other hydraulic system issues can lead to overheating as well. Some solutions to overheating problems may require you to make larger changes to your hydraulic system. If the culprit for your system's overheating isn't an obvious one, then have a professional service inspect and repair your system.

At Carolina Hose & Hydraulics, we can help you troubleshoot your hydraulic system issues. If you need repairs, replacement parts, or servicing for your hydraulic system,

contact us today.