SHOULD YOU REPLACE YOUR HYDRAULIC HOSE ASSEMBLIES?

Large pieces of hydraulic equipment can make the completion of essential tasks much easier. If your company relies on hydraulic equipment each day, you should take the time to maintain your equipment properly.

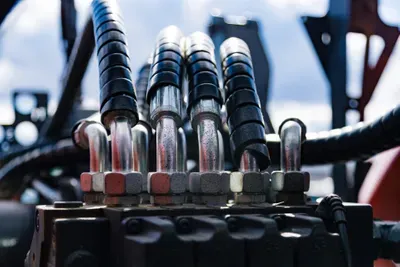

Hose assemblies act like the cardiovascular system within a piece of hydraulic equipment. Hydraulic fluid goes through the hose assembly to the various components that work together to make a piece of equipment function. Hose assemblies that are damaged or beginning to deteriorate can be costly.

An unexpected hose assembly failure can bring production to a halt, costing your company time and money. Hose assemblies do have a finite lifespan, so you need to be proactive in determining when you should replace your hose assemblies to maximize both production and value.

Schedule a Visual Inspection

The easiest thing that you can do to manage the performance of your hydraulic hose assemblies is schedule routine visual inspections. A visual inspection allows someone to evaluate all of the hoses and assembly components that exist on a given piece of machinery.

Careful visual inspection can identify cracking, loss of flexibility, or slipped fittings - all warning signs of impending hose assembly failure.

You can replace the hose assembly as soon as a visual inspection identifies a problem to avoid having an unexpected loss of hydraulic power from faulty hoses in the future.

Perform an Operational Test

Some types of hose assembly damage might not be readily apparent with a simple visual inspection. If no issues are spotted during a visual inspection, you should conduct an operational test to check for potential hose damage.

An operational test lets you evaluate your hose assemblies when the hydraulic systems they serve function at maximum pressure. This increase in pressure is critical when identifying any potential damage to the hoses that run throughout your hydraulic system, but you should never exceed the maximum pressure rating for your individual hoses.

Most companies do not operate their hydraulic equipment at maximum pressure for extended periods of time, which allows minor hose damage to go unnoticed. Conducting an operational test might be the only way to identify seemingly insignificant hose damage that could turn into a major headache if the affected hose assembly is not replaced.

Consult the Recommended Replacement Guidelines

Consulting the recommended hose replacement guidelines for your heavy machinery to help you avoid costly repairs caused by a damaged hose.

You can't predict exactly how long your hose assembly will last. Environmental factors like ambient temperature, hose size, operating pressure, and the type of hydraulic fluids that you use will play a role in determining the lifespan of your hose assembly.

You can maintain a log that identifies when hose assemblies are replaced on your heavy machinery, and compare this log with the recommended replacement guidelines to make any necessary adjustments.

Use the recommended guidelines as a baseline, then adjust your hose assembly replacement schedule accordingly based on the unique conditions in which your heavy machinery operates.

Hydraulic hose assemblies are critical to the performance of your heavy machinery. You can invest time and effort into the selection and installation of your hose assemblies, but unexpected wear and impact damage could shorten the lifespan of your hoses if you do not monitor your hose assemblies carefully.

Routine visual inspections, operational testing, and scheduled hose replacement will help you maintain efficiency, increase production, and extend the longevity of your hydraulic hoses.

Contact Carolina Hose & Hydraulics to learn more about the benefits of proper selection, installation, and care of your hose assemblies. We look forward to speaking with you and meeting all your hydraulic hose and equipment needs.