IMPLEMENT A FOLLOW-UP PLAN AFTER HEAVY EQUIPMENT FAILURE

When an important piece of heavy equipment fails, your troubleshooters or mechanics must work quickly to get it running once more. Workflow slows or halts altogether while a crane, bulldozer, or excavator sits idle, making troubleshooting necessary.

What Does Troubleshooting Include?

Traditional troubleshooting practices consist of a few familiar steps:

- Verify a problem exists by gathering details from the operator most familiar with that piece of equipment.

- Narrow down the cause of the problem by testing equipment and physically examining key equipment components.

- Complete any necessary repairs or maintenance to eliminate the cause of breakdown.

- Verify the problem is truly corrected with tests and retests before returning the equipment to work.

However, an often overlooked but crucial final step is necessary to limit or prevent similar issues in the future.

What is a Follow-Up Plan?

A follow-up plan is the concluding step that good troubleshooters and mechanics practice each time a piece of equipment is repaired and placed back into service. Sometimes just locating and repairing equipment problems and following up with test and retest is not enough. Without good follow up, the long term productive performance of the equipment piece is hurt.

A solid follow up plan consists of several different actions, which vary according to equipment type, work environment, nature of breakdown, and other factors.

Conduct Operator Awareness Training

Often equipment failure happens because of the performance or behavior of an operator. For example, an operator may try to lift too much weight in a particular excavator. Conducting operator awareness training after a repaired equipment piece re-enters work is a way to prevent future equipment failure.

Training not only helps reinforce standard safety rules, but helps operators deal with other factors like work stress, sensory overload, and fatigue. Factors like these often contribute to equipment use that leads to failure or breakdown.

Alter Preventive Maintenance Schedules

Regular preventive maintenance is necessary to help keep machines running smoothly and for longer periods. Manufacturers provide a suggested maintenance plan for each piece, and adhering to that schedule prevents a voided warranty. Most schedules consist of monthly, yearly, or mileage tasks. However, you may need to alter that schedule as part of your follow up plan.

Remember, suggested manufacturer maintenance is pertinent only under normal operating conditions. Maintenance recommendations need to change if you use equipment in extreme climate or weather conditions. Dirt and debris can contaminate fluids more quickly when you operate machinery in particularly dusty or muddy environments. Factors like these warrant a modified maintenance program to prevent future breakdown.

Keep a Detailed Record of Problems

After troubleshooting is successfully completed, keep a detailed record of the problem. Doing so ensures any similar problems in the future are easily reviewed. This method is especially helpful when several different mechanics are present at the site that may not be immediately familiar with some equipment pieces.

Include details when documenting the problem, how it manifested, and what task was involved, as well as details regarding the repair.

Change Component or Service Suppliers

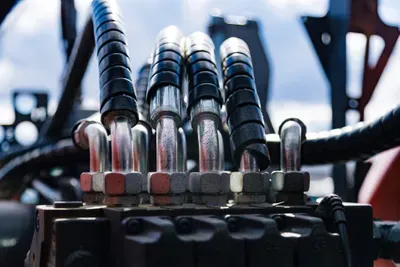

Sometimes your troubleshooting system can reveal the same problems over and over. When breakdowns are associated with the same part or component repeatedly, there may be a problem with parts from a specific supplier. Hydraulic fittings, seals, and tubing replacements can be especially problematic when they are dirty to begin with, or of a lower quality in efforts to be more economical.

If this is the case, it's time to look for a change in who supplies your parts or other services. Additionally, look for a supplier that is able to provide parts on demand so machine downtime is kept to a minimum.

Carolina Hose & Hydraulics has options for your hydraulic component needs. Give us a call when you want to improve your troubleshooting methods with a good follow up plan involving the best component supplier.