3 THINGS YOU CAN DO TO PREVENT HYDRAULIC CYLINDER FAILURE

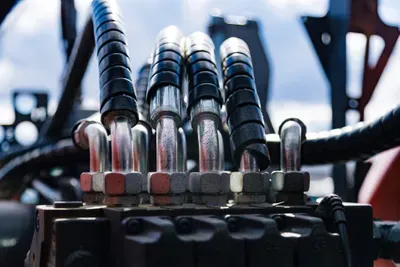

Hydraulic cylinders are central components in many of the heavy machines used in industrial or manufacturing facilities. A hydraulic cylinder provides directional force to an object by either pushing or pulling the object.

Pressurized fluid fills the cylindrical portion of a hydraulic cylinder. This fluid forces a rod to move out the bottom of the cylinder, creating the power needed to generate movement.

Since hydraulic cylinders are components that tend to be in continuous motion, the potential for cylinder failure is always present. You can be proactive in protecting your hydraulic cylinders against some of the more common reasons behind cylinder failure to avoid production downtime and costly repairs in the future.

1. Maintain Hydraulic Seals

Maintaining a constant supply of pressurized liquid within the hydraulic cylinder is essential if the cylinder is to work properly. Specialized seals help to create a leak-proof connection between the cylinder and the moving rod. If the seals in a hydraulic cylinder go bad, fluid can leak from the cylinder and cause a loss of power.

You can easily avoid seal leakage by taking the time to care for your hydraulic seals properly. Schedule routine visual inspections of all seals within your hydraulic systems. Check for evidence of hardening, cracking, and overall wear.

Use caution when storing hydraulic seals to ensure they don't sustain damage prior to installation. Seal replacements should be handled with care, as an improper installation could weaken the integrity of the seal and result in hydraulic fluid leakage over time.

2. Prevent Fluid Contamination

An adequate supply of hydraulic fluid contained within each cylinder isn't enough to keep maintain peak performance; the fluid also needs to be clean and free from contaminants. Contaminated fluid has the potential to wreak havoc on the mechanical systems within your heavy machinery.

Moisture is one of the most common types of hydraulic fluid contamination found in industrial settings. Store your fluid reserves in airtight barrels away from exposure to sunlight or temperature fluctuations. This will prevent a phenomenon known as breathing, which is a process whereby water can infiltrate storage barrels as they expand and contract.

Only open fluid containers in a clean environment, and thoroughly flush out the hydraulic system before new fluid is added. Taking these precautions should help you avoid fluid contamination, and the potential problems that go along with contaminated hydraulic fluid.

3. Keep Rods Straight

Alignment issues between the hydraulic cylinder and the rod that is forced out of the cylinder by the pressurized fluid can lead to cylinder failure over time. The rod can become bent if the weight of the load it is moving is greater than the force generated by the pressurized fluid inside the cylinder.

Bent rods can scrape against the interior walls of the cylinder, making the cylinder more susceptible to corrosion. Rod seals are also at risk of being torn or damaged when the rod is bent.

A dial gauge should be used to regularly test the straightness of your hydraulic rods. Any rods that fall outside acceptable straightness parameters must be repaired using a press, or replaced with new rods to preserve the integrity of your hydraulic cylinders.

The quality and condition of the hydraulic cylinders installed in your industrial machines can have a direct impact on the performance of your machinery over time. Cylinder failure is something that should be avoided at all costs. You can be proactive in preventing cylinder failure by maintaining seals, preventing fluid contamination, and ensuring rod straightness at all times.

Carolina Hose & Hydraulics has the knowledge and experience needed to service your hydraulic cylinders.

Call us today to learn more about preventing costly hydraulic cylinder failures in the future.