SIX MAINTENANCE MISTAKES IT'S IMPORTANT TO AVOID WITH YOUR HEAVY EQUIPMENT

At any industrial facility, a great deal of demand and stress are typically put on heavy equipment. Proper maintenance is important to both avoiding downtime due to malfunctions and extending the lifetime of expensive mechanical equipment.

Unfortunately, many owners and managers allow a lot of detrimental mistakes to take place regarding heavy equipment maintenance that drastically detract from the company's bottom line.

The following are six maintenance mistakes it's important to avoid with the heavy equipment at your facility to maximize your bottom line profits and minimize any operative headaches for your staff members:

Failing to Plan for and Implement a Preventive Maintenance Program

Without a preventive maintenance program, it's going to be hard to keep up on routine maintenance that is essential to the proper functioning of your heavy equipment.

The only way to ensure that you handle maintenance properly is to make it routine. A routine maintenance schedule can show a lot of benefits for your facility. It can reduce the occurrence of unexpected breakdowns, improve the overall reliability of your system, and maximize the resale value of any heavy equipment you decide to get rid of and replace.

Ignoring Performance Specifications

It's important to look at the performance specifications recommended by the manufacturer in determine the amount of demand you can put on your heavy equipment on a regular basis.

If you're exceeding the performance specifications recommended by the manufacturer, it might be best to purchase multiple equipment pieces to avoid wear and tear from costing your company a lot of money over time.

You should not only pay attention to performance specifications when it comes to usage amount, but also when it comes to other factors such as weight capacities. Exceeding weight capacities will not only wear out your equipment prematurely, but can also cause safety hazards at your facility.

Not Adequately Training Operators of Heavy Equipment

Any training you can offer to your operators could save you a lot of money down the road. Shirking on training efforts won't only compromise the long lifespan of your equipment, but could also compromise the safety of your facility.

Go overboard on equipment use training. You should make a special effort of training even everyday operators on the mechanics of the machines they use. This way, they could become aware of operative tendencies that tend to prematurely age mechanical components.

Overlooking Simple Cleanings

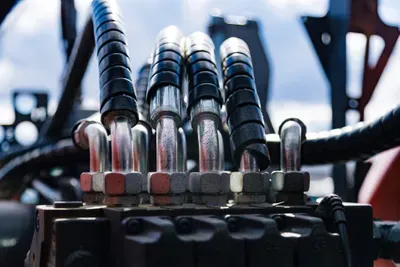

Heavy machinery typically includes a great deal of filters and seals that need to be kept clean and promptly changed to ensure the proper functioning of equipment pieces.

Simple cleanings of the exterior of machinery can also go a long way in keeping dust and contaminants out of machinery. This way, contaminants won't interfere with air circulation and other essential processes that keep equipment functioning properly.

Not Taking Protective Measures with Wires and Electrical Components

Unfortunately, electrical components and wires can easily become damaged by contamination from debris and the elements. Protecting wires and electrical components is an essential step in ensuring the continued good condition of heavy equipment.

Not only should you look out to protect wires, but you should also make sure that essential parts like starts and alternators are covered by some sort of protective case. Remember that it can be expensive to replace these essential components once they become damaged, so look out for them to avoid malfunctions.

Improperly Storing Heavy Equipment

It might be surprising that significant damage can actually take place while heavy equipment is in storage. If you leave equipment in storage for significant periods of time, you need to make sure that it is protected from temperature extremes and moisture exposure that could lead to problems like corrosion.

You can be sure that heavy equipment at your facility is properly maintained with the

heavy equipment maintenance services of Carolina Hose & Hydraulics.